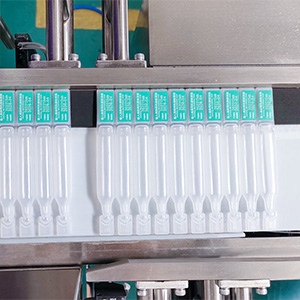

BFS technology refers to the advanced manufacturing technology that integrates the three process steps of blow molding, filling, and sealing of hot-melt plastic parisons on the production line into a single piece of equipment for continuous aseptic filling production. Since the first BFS machine was introduced in 1962, BFS technology has been in use for nearly 60 years. Today, BFS technology has a much broader range of applications. It can be used for the production of aseptic liquid preparations (solutions, emulsions, suspensions) and aseptic semi-solid preparations (gels, creams, and ointments), and it is also used in the production of non-aseptic products. Santuo keeps pace with the times, adapting to market demands by developing and designing BFS-related equipment such as light inspection, leak detection, labeling, cartoning, boxing, and palletizing, providing solutions and technical support for BFS product manufacturers.