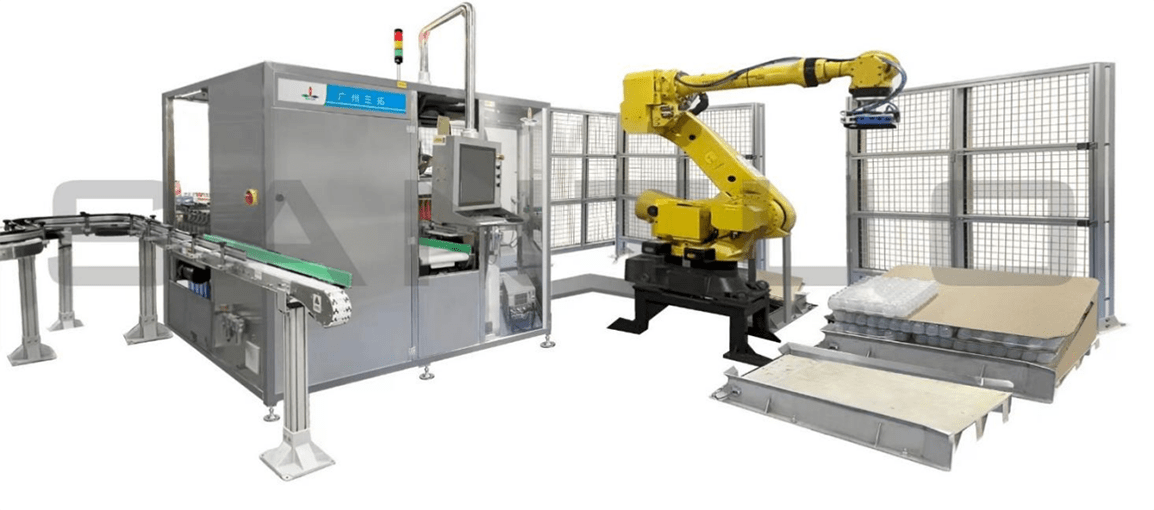

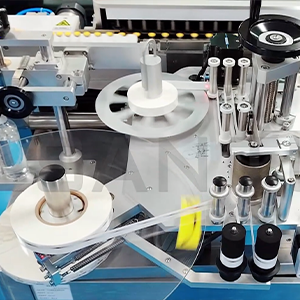

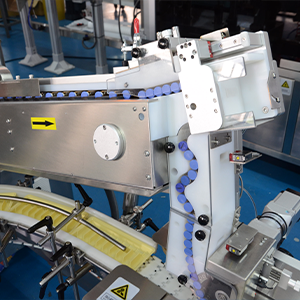

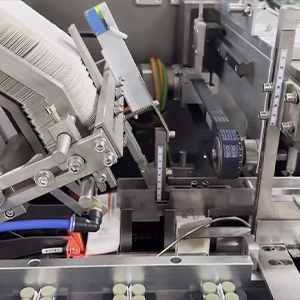

The packaging solution for the vial bottle is designed with the concept of saving labor, reducing costs, saving installation space, and improving efficiency, based on the layout and structure of the plan. The system uses PLC to coordinate the interlocking control between various devices, achieving the goal of improving production efficiency through coordinated operation. Before packaging, robots are used for automatic de-stacking and bottle handling, also the empty bottle detection and rejection address the inefficiency of manual bottle handling and to avoid the possibility of cross-contamination. From automatic tray separating to light inspection, labeling, and tray insertion, to the final automatic palletizing by robots, the overall solution is completed by machine automation. This includes information prompts for material shortages, system self-checks, and common fault alarm information prompts, aiming to achieve the highest level of automation. The goal is to free users' hands and improve overall efficiency.