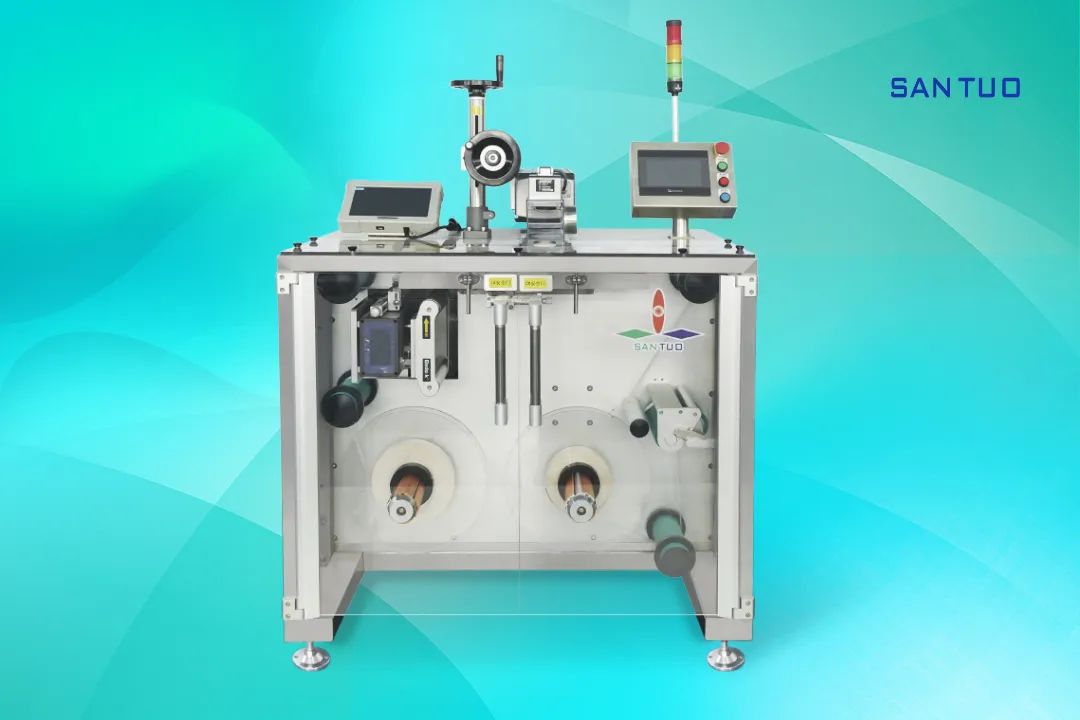

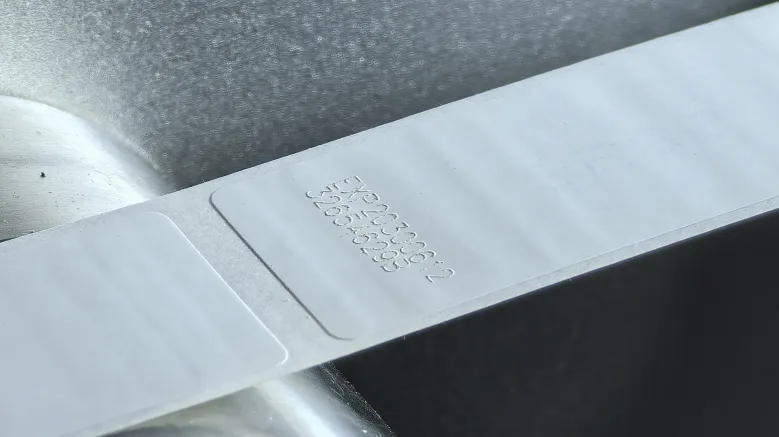

The function of the vertical label rewinder is to transfer labels from one roll to another, performing various functions such as label counting, quality inspection, inkjet printing, coding, code inspection, barcode reading, and label direction change during the rewinding process. These functions can be flexibly selected according to needs.

This equipment is mainly used for coding and inkjet printing on rolled labels or films, label counting, or label direction change. It is particularly suitable for label management in the pharmaceutical industry, label quality inspection in the printing industry, and coding on food and pharmaceutical packaging films.

Functional Features

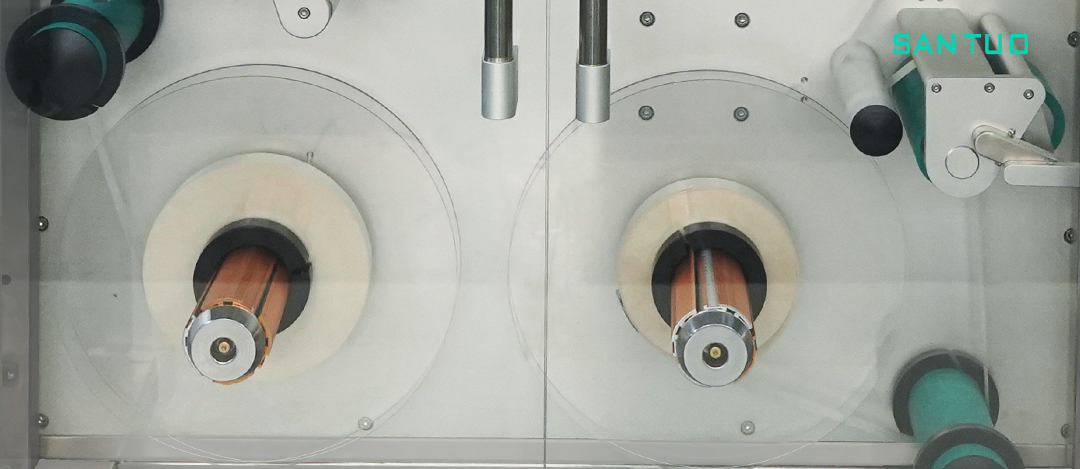

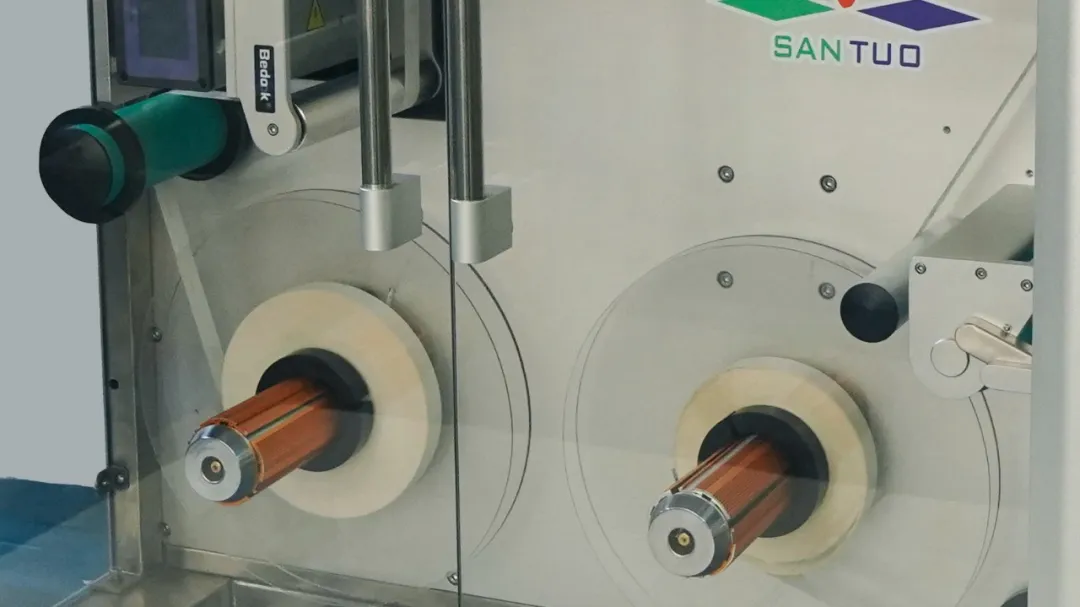

- Adopting a pneumatic tension shaft for easy loading and unloading of label rolls.

- Utilizing a deviation correction controller to ensure neat rewinding of labels.

- Equipped with a touch screen for convenient operation, featuring a label count display, in line with human-centered design.

- Structurally, it has reserved installation positions for lasers, coders, or synchronizers to meet diverse needs.

- Capable of rewinding labels to change the winding direction of the label roll, while also achieving label counting.

- It can be equipped with a vision Inspection system to inspect and mark labels with printing quality defects.

Technical Specifications

|

Standard Internal Diameter of Label Roll |

76mm |

|

Maximum External Diameter of Label Roll |

400mm (customizable upon request) |

|

Maximum Width of Label |

200mm (customizable upon request) |

|

Maximum Rewinding Speed |

45 meters per minute |

|

Working Air Pressure |

≥0.6Mpa |

|

Power Supply and Power |

220VAC 50Hz 750W |

|

Dimensions (L×W×H) |

1173×776×1820 mm |