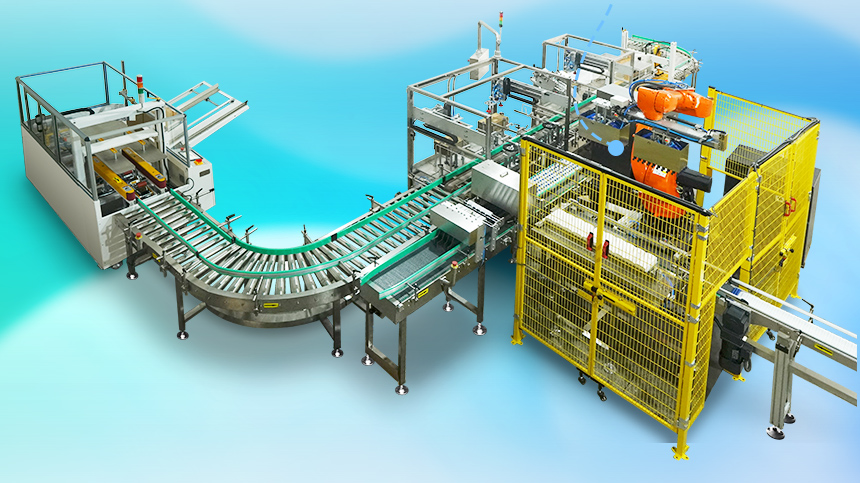

The automatic cartoning packaging line mainly consists of three major parts: carton opening, cartoning, and sealing. It can separately convey two types of products, bare bottles and boxed items, which converge at the cartoning area awaiting assembly. The robot features a dual-station fixture design, capable of picking up two layers of products at once and then moving the fixture to place them in two separate cartoning stations, where the cartons are waiting to be filled. The robot performs a reciprocating motion, completing the tasks of stacking products for cartoning, inserting paper dividers and instruction manuals, and finally sealing the cartons at the sealing machine. This production line is suitable for industries such as pharmaceuticals, daily chemicals, and food.

Functional Features

- The design incorporates independent sorting and grouping stations and two boxing stations, allowing for boxing of two different types of packaging products—naked bottles and boxed items. The robot separately picks up corresponding products for boxing, saving installation space and labor costs.

- The robot's dual-station fixture design matches two cartoning stations, enhancing the efficiency of the production line equipment.

- Various cartoning and packaging processes are implemented: insertion of bottom dividers, product stacking, insertion of middle dividers, insertion of top dividers, and insertion of instruction manuals, meeting users' high-quality packaging requirements for products.

Technical Parameters

|

|

Category |

50ml |

100ml |

|

Product |

Bottle |

φ39.7×H74.5mm |

φ45.5×H101.1mm |

|

Box |

L200×W80×H80mm |

L232×W93×H107mm |

|

|

Boxing Speed |

Bottle |

up to 5 boxes/min |

up to 9 boxes/min |